How to balance a centrifuge and why it is so important to have a balanced centrifuge

March 07, 2023 | Centrifuge

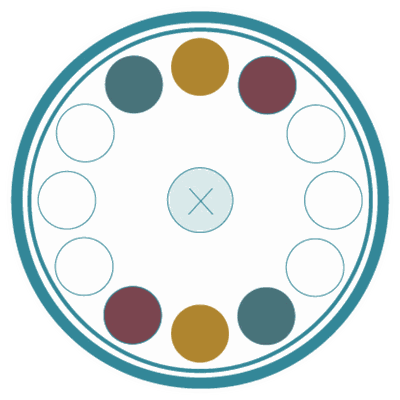

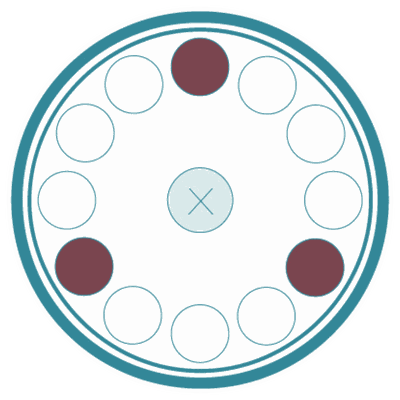

Swinging bucket rotor devices. Make sure that all rotor positions are equipped with buckets, regardless if you leave them empty or not. Moreover, you need to inspect if the buckets can swing out smoothly.

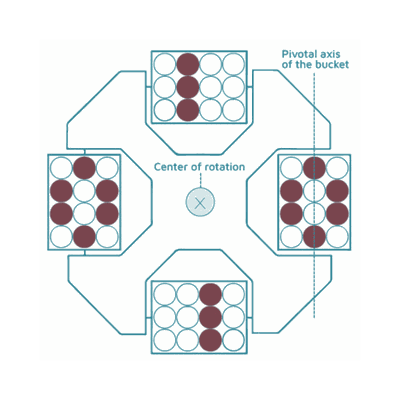

During the loading of tubes into the buckets, see to it that the opposing buckets are loaded symmetrically to avoid imbalance across the center of rotation. Additionally, each bucket has to be balanced across its pivotal axis. If these conditions can’t be met with the sample tube number that you have, use ‘balance tubes’ to help.

Centrifuge Safety Precautions

In operating the centrifuge, it is crucial to do the following:

- Always ensure a sturdy, level worksurface. An uneven surface can cause your rotors to be imbalanced, even before you have loaded your tube samples.

- Do not open the lid while the rotor is functioning. Though many centrifuges have a ‘safety shutoff’, this can stop power to the rotor which will still spin to its own inertia until such time that it is slowed to a stop by friction.

Pull the plug if the centrifuge is wobbling or shaking. Excessive shaking or wobbling can mean danger. Double-check if the tubes are in place. If the shaking is still not resolved, do not use the centrifuge until it has been serviced by the manufacturer.

Centrifuge care and maintenance

These few simple steps can keep your centrifuge functioning properly, and consequently keeping them balanced.

- Keep it properly lubricated. O-rings, which are the main source of protection against a sample leakage, must be lubricated prior to installation of a new rotor or after cleaning. Threaded components should also be cleaned regularly with a recommended grease to avoid corrosion.

- Ensure proper training of lab personnel on operating the equipment. This includes making sure that the buckets are seated in their pins, balancing the tubes, operating rotors based on stated guidelines for speed and maximum compartment mass, and avoiding scratching the rotor.

- Examine critical components. Look for signs of wear and pay close attention to any noise or vibration. If any of this occurs, discontinue unit use.

Daily cleaning. Clean the centrifuge and its accessories or interior portion with neutral cleaning solutions and a soft cloth. Moreover, be aware of the different types of samples used with centrifuge and any specific protocol necessary if spillage happens.

Balancing your centrifuge, and using the right tubes alongside it, are the most crucial aspects of centrifugation safety and maintenance. You can now enjoy massive throughput while ensuring trouble-free and safe operations!