Lab Shakers 101: Getting to know which shaker is best for your Application

March 22, 2023 | Sample Preparation

Mixers are one of the most utilized instruments in many lab applications. Mixers come in shakers, rockers, rotators, and others that have varying configurations (capacity, speed, duration, slope, and more) and are used according to specific applications. Mixers are highly useful for basic experimentation, particularly in sample preparation.

The diversity of these mixing instruments depends on the nature of the samples used in an application. Here, we discuss one particular mixing instrument—orbital shakers, and their common applications so you’ll know which is the best type to use in your work in the lab.

The Basics of Shakers

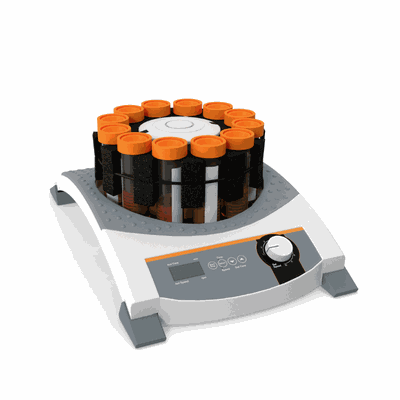

Orbital shakers are primarily used in applications like culturing microbes, agitating substances, and general mixing and blending of samples. Shakers have a platform that moves in a circular motion, which causes the liquid in the containers to move in a similar fashion. The agitation provided by the shaker helps to promote oxygenation and nutrient availability, which is beneficial for the growth of cells and microorganisms.

Consequently, orbital shakers are commonly used in microbiology, cell culture, and chemistry laboratories. Orbital shakers available on the market include benchtop shakers, floor-standing shakers, and incubator shakers. Some models may also include features like temperature control, humidity control, and programmable shaking patterns.

Differentiating Lab Shakers, Rockers, and Rotators

Lab shakers, rockers, and rotators are all laboratory instruments used for agitation and mixing, but they operate in slightly different ways. They are greatly varied in terms of the motion and rhythm that they follow in agitating and mixing samples.

Lab Shakers as mentioned earlier move in a circular motion called orbital shaking. This motion allows the contents of the containers on the platform to move in a similar fashion, making them useful for mixing, blending, and aerating liquids.

Lab Rockers on the other hand move back and forth like a seesaw via motion called reciprocal rocking. Such is useful for low-speed mixing and agitation of samples.

Lab Rotators, sometimes called tube rotators, are instruments that rotate tubes or other containers around an axis. They are useful for the gentle mixing and suspension of cells or particles, such as for cell culture or protein expression.

Each instrument is specialized in certain applications. Shakers are best for mixing liquids, rockers are best for gentle agitation of samples, and rotators are best for suspension and mixing of cells or particles.

Digital vs. Analog Shakers

Shakers mainly come in two common models: Analog and Digital. This shaker machine employs the same purpose but has distinct features that allow them to operate differently.

Analog shakers use a simple motor to rotate an eccentric weight, causing the platform to shake. The speed of the shaker is adjusted by a manual dial or knob, which may make it difficult to accurately set and maintain the desired speed. Analog shakers however are generally less expensive than digital shakers, but they may be less precise or reliable, and could also require maintenance annually.

Digital shakers contain more features than analog models. The machine uses a sophisticated mechanism to control the speed and motion of the platform. It has a digital display and control panel, which allows users to set and monitor the speed, time, and other parameters. Some models even offer programmable shaking patterns and other advanced features. Digital shakers are generally more expensive than analog shakers, but they offer greater accuracy, precision, and control.

Types of Orbital Shakers

Orbital shakers come in different sizes, forms, and operational designs. The following are the common types of shakers:

Benchtop orbital shakers: These are the most commonly-used shakers in laboratories and is the lowest cost options available. They perform ideally in applications that require ambient temperatures such as staining, some solubility studies, extraction procedures, and washing procedures. They come in various sizes and capacities, from small and compact models to larger, more heavy-duty units.

Floor-standing orbital shakers: These are larger shakers that look like a refrigerator cabinet designed to accommodate bigger sample volumes and heavier containers. It that can shake as large as 4 liter Erlenmeyer flask and up. This type is commonly used in industrial or biotech settings and can be equipped with additional features like temperature control or humidity regulation.

Incubator orbital shakers: These are primarily designed for use in incubators or other temperature-controlled environments, allowing you to shake samples while maintaining a consistent temperature.

Refrigerated orbital shakers: These are designed for built-in refrigeration units that allow for precise temperature control, even at lower temperatures. These shaking equipment are useful in applications like cell culture or microbiology where temperature control is critical.

Multi-tiered orbital shakers: These shakers have multiple tiers or shelves that allow for multiple samples to be shaken simultaneously, increasing throughput and efficiency. This is commonly used in applications like high-throughput screening, drug discovery, and diagnostic testing.

Microplate orbital shakers: These are designed specifically for shaking microplates that hold small volumes of liquids or samples. This shaker equipment is most useful for applications such as cell culture, enzyme assays, and ELISA (enzyme-linked immunosorbent assay), which require precise and consistent shaking of microplates.

Rocking orbital shakers: These shakers move samples in a back-and-forth motion, rather than a circular motion like traditional orbital shakers. They are ideal for applications like mixing or hybridization.

Things to consider in choosing your orbital shakers

A good guide to choosing the right and best orbital shakers for your lab includes the following considerable factors below:

Capacity: A good shaker should be able to accommodate the size and number of containers you need to use. Most shakers available on the market have a 2.5 cm and 5.1 cm orbit diameter. Experiments involving 2 liters and more or containing shear-sensitive cells, will benefit from an orbit with a larger diameter. Small orbit diameters on the other hand are best for microcentrifuge tubes, microplates, and other extra small vessels.

Speed range: The speed of the shakers is also important. The agitation rate could affect the oxygen transfer rate which is an important parameter for applications like cell cultures wherein cell culture growth may be affected.

In relation to capacity, shakers with larger diameters tend to have a lower maximum speed. Generally, shakers have speeds as fast as 500 rpm, while others could shake as low as 15 rpm.Motion type: As previously mentioned above, shakers often move in a circular motion, but some models may also offer linear or reciprocal motion. The motion of your shaker machine is important to carry out the needs of your application. If your work requires varying motion types in your orbital shaker, considering digital shakers may be a good option.

Temperature control: Some shakers offer temperature control, which can be important for applications such as cell culture. For instance, some shaking incubator provides temperature that can go up to 80ºC which are necessary to grow thermophiles. Some may also have models that can refrigerate to as low as 4ºC. There could also be an option to go with a shaking water bath which offers temperature controls as well.

Programmability: Some shakers offer programmable shaking patterns, which can be useful for repetitive or complex applications. Generally, some shaker equipment has a user interface that allows the operator to input the desired shaking parameters such as speed, direction, and duration. This is an advantage especially when your application involves optimizing growth conditions, improving yields, and ensuring consistency between experiments.

Noise level: Shakers can be noisy which may affect or disrupt your laboratory environment. Noise in orbital shakers usually comes from the motor, airflow, or even vibrations in the surface on which you placed your laboratory shakers. Choosing models which are designed to produce less noise may be a good thing to consider.

Durability: Orbital shakers are a significant investment, so choosing a model that can withstand long periods of work, requires less maintenance, and offers warranty service is a plus. It will be good if you take the time to review customer feedback on the model that you're eyeing to purchase.

Cost: Lastly, orbital shakers can be costly. Checking if the lab orbital shaker that you’re eyeing fits within your laboratory's budget is important. Most shaker lab equipment can range in price from approximately $1,500 for small open-air bench-top models to $15,000 or more for large stackable shakers. A final takeaway is to be mindful that while cheaper models may be more affordable upfront, they may not offer the same level of performance or durability as more expensive models.

In conclusion, it’s important to choose a shaker that meets your specific needs and requirement, whether you are working with small or large volumes, delicate samples, or high-throughput applications. But it should also level your capacity to purchase them. Taking the time to carefully evaluate your options and invest in a quality orbital shaker can save you time, money, and frustration in the long run.

With the right orbital shaker, you can achieve the shaking and mixing results you need for your laboratory research and applications.