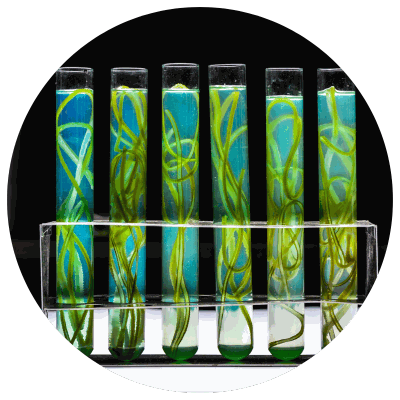

Technology that prevents fouling in bioreactors for better CO2 capture

May 05, 2023 | Biotechnology

Algae cells naturally have a small negative electric charge on their membrane surfaces and the team thought of using electrostatic repulsion to push excess algal growth away. A negative charge is created on the vessel walls, using high-performance dielectric material or an electrical insulator with high permittivity. With only a small voltage, this material causes a change in surface charge. This electrostatic interaction does not not shock the algal cells and the scientists are able to control cell adhesion. And since it isn’t cell specific, there is potential for using it with other cells, such as mammalian and bacterial cells.

The team used both silicon dioxide and hafnium oxide as dielectric materials and they proved to be more efficient compared to conventional plastics used in making photobioreactors. These materials can be applied in a coating that is thin (10 to 20 nanometers thick) to a photobioreactor system.

Depending on the application, the system has massive implications and can be used to either repel or attract cells by the reversal of voltage. A similar setup can be done with human cells in the production of artificial organs by introducing a charged scaffold that could attract cells into the right configuration. Seeing its effectiveness in lab-scale tests, this technique can be assimilated to commercial production with the incorporation of new developments.